BOATS

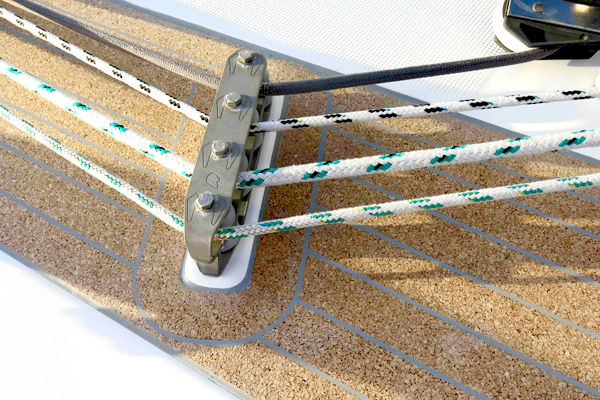

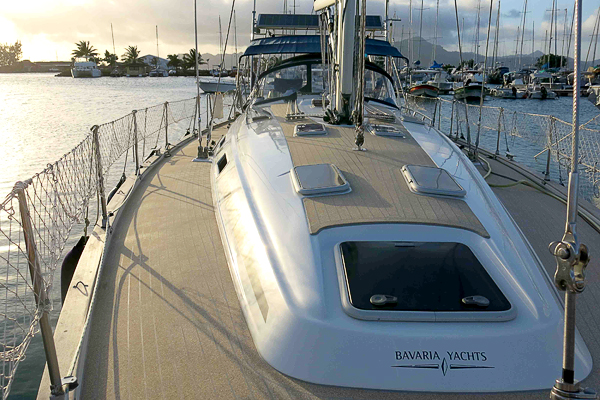

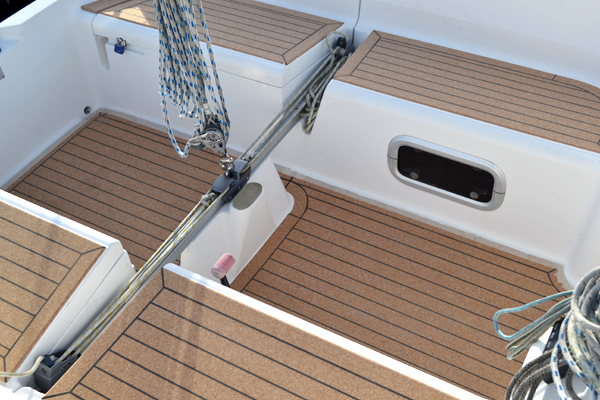

DECK

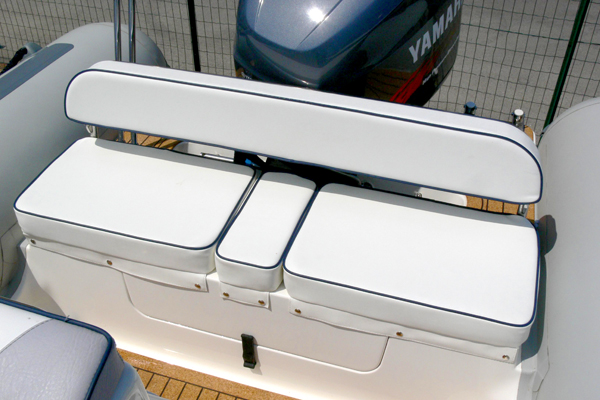

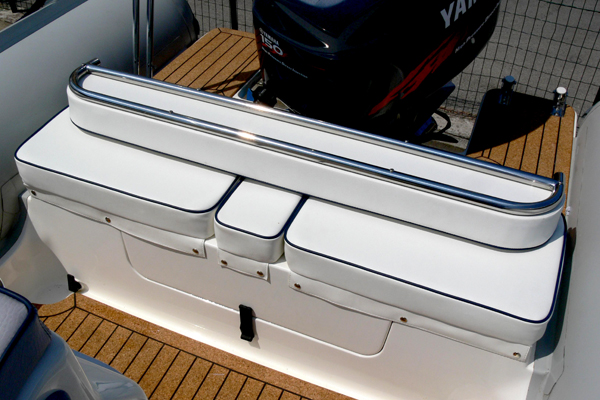

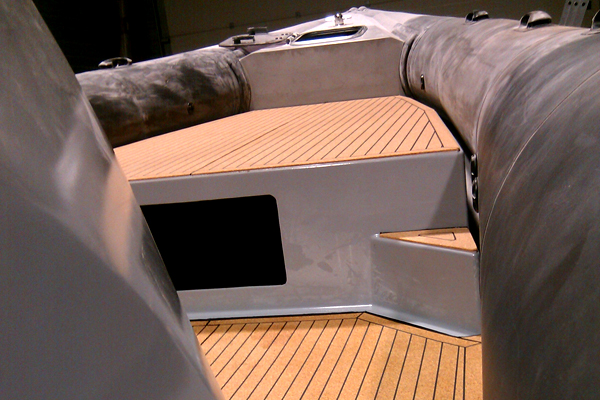

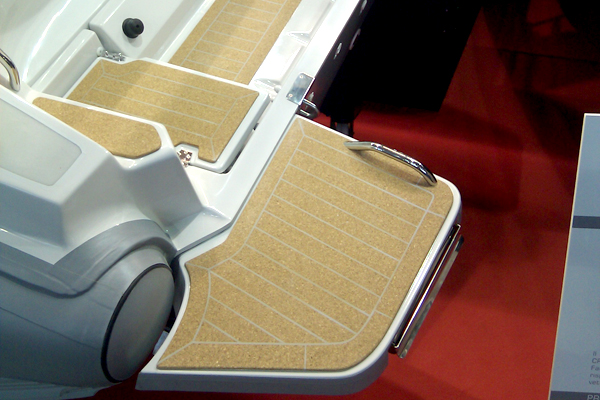

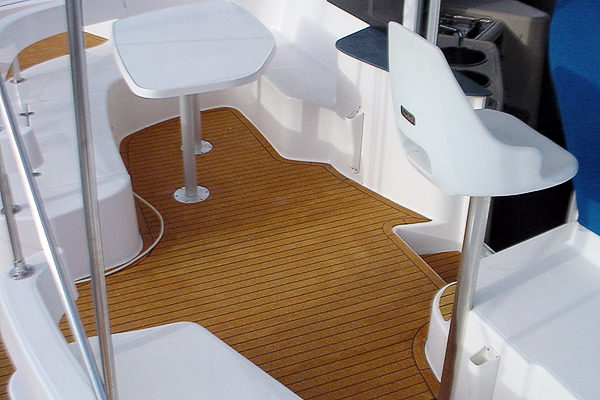

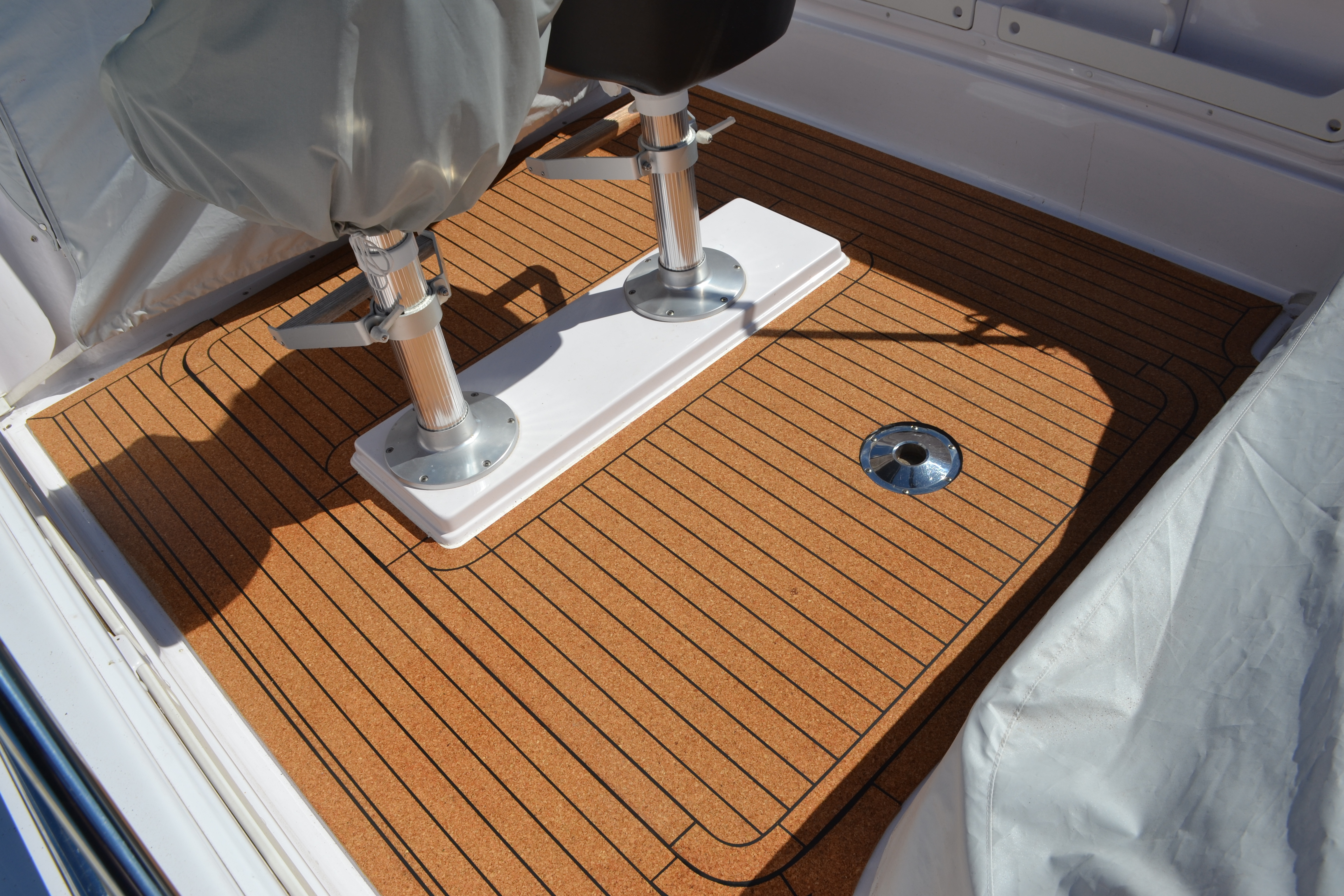

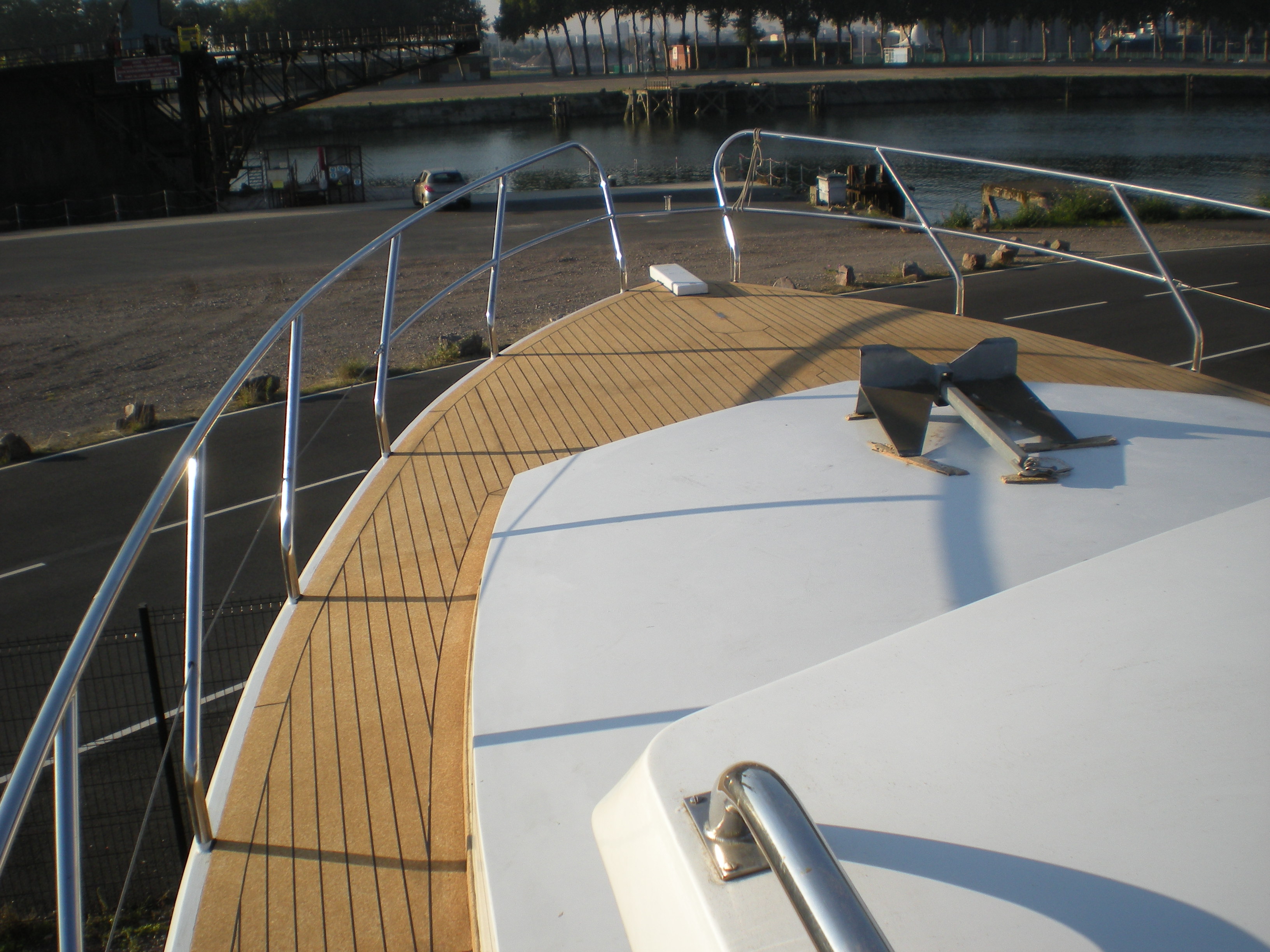

Seacork Deck has been laid down since 2002 on boats of all types and sizes.

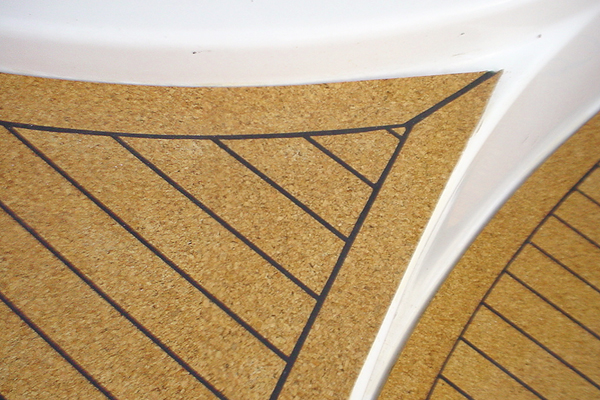

Cork itself has been used on boats for centuries because of its many attributes: anti-slip when wet, does not get hot in the sun, dampens vibrations, will not rot, anti-bacterial, and much else.

COMFORT

Your bare feet will feel the difference with every step. Soft and never hot, Seacork Deck beats all other decking materials for comfort.

SAFETY

Seacork Deck’s anti-slip properties provide an unrivalled level of safety on boat decks. Good maintenance is necessary to maximise the safety features.

HOW IT LOOK

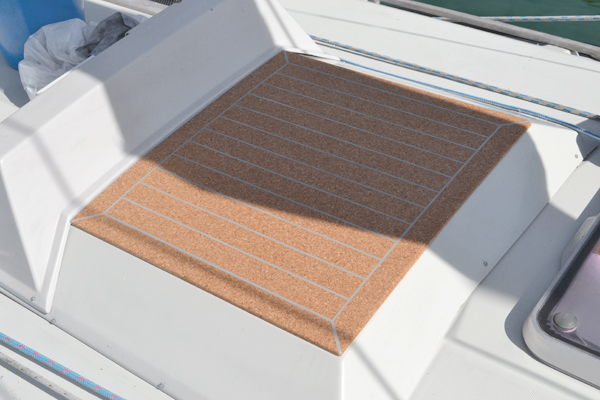

Cork’s natural look reinforces the fact that it is the most ecological decking material available today. We can decorate the cork with stripes or almost any design you can furnish.

ural.

WEAR AND TEAR

Many of the first Seacork decks, laid in 2002, are still in use and show no signs of wearing out.

VALUE FOR MONEY

Time saved in money saved.

RIB

MULTIHULL

MOTOR BOAT

DAY CRUISER

SAIL BOAT

YACHT

TECHNICAL INFO

Thermal insulation measured at 20° C. Thermal capacity > 1500 J/kg. Thermal diffusion < 1.60.10-7 m². Thermal conductability 0.05/0.06 W /mK.

UPKEEP

You can use any of the cleaning products sold in supermarkets and a brush with hard bristles, just as you would for cleaning a tiled floor. It is just as easy to clean a cork surface as tiles but some precautions must be taken.

Mix any cleaner with water in a bucket according to instructions on the package and start brushing. Wait a few minutes before repeating the operation. Then rinse thoroughly to get rid of all traces of the cleaner.

Seacork Deck.

Avoid additives. Too much sealant does create a protective film but this inhibits the cork’s anti-slip properties. Similarly, oils used for wood makes the cork slippery. So does detergent if it is not sufficiently rinced.

INSTALLATION

This is normally a job for a professional although some of our customers have done it themselves successfully.

RESELLERS

WHAT OUR CUSTOMERS SAY

- Howzit Everyone,

Some photos of the Seacork on my Hatteras sport fisherman based in Dubaï.

The first 3 were taken yesterday by her new owner.

The others were from when we launched after refit in 2012.

Unfortunately the current photos would be better if it had been given a good clean.

It looks as if the cork has held up well but the caulking needs attention. Keep in mind that this has been uncovered and in a very harsh climate for the last 8 years.

I am very pleased with the products performance.

I would definitely use it again.

Regards

Marc A.

Seacork Hull, when sprayed on the inside walls, eliminates condensation and provides a high degree of thermal and acoustic insulation in the cabin. Moreover, it takes up far less space than ordinary insulation (which is far less efficient). Seacork Hull is sometimes used on decks as an alternative to anti-slip paint but Seacork Deck (cork sheets) are a much better choice.

COMFORT

In so doing, Seacork Hull eliminates condensation. This greatly reduces dampness inside the boat. It provides considerable acoustic damping too.

Seacork Hull has an insulating effect but it provides only limited insulation. You can cover the cork (or not) with an insulating material to have much better control of the temperature inside.

Any insulating material will be better than none. Expanded cork will give the best results. We have special adhesives for this purpose.

Putting insolation on top of Seacork Hull, if only to restore structural volume, should be done before applying any decorative wall covering.

LONGEVITY

WEAR AND TEAR

If there is a vairage, scratches can leave traces on the cork granules. You can cover them with acrylic paint.

VALUE FOR MONEY

Time saved is money saved.

TECHNICAL INFO

Seacork Hull contains a much higher concentration of resin that any similar product in today’s market. This ensures the highest possible guarantee against peeling regardless of the surface on which it is sprayed.

Seacork Hull is made mostly from recycled materials of which wine bottle corks represent a very large part. Different tests show that it meets current standards for waterproofing, microfissures, and so forth. The results of these tests are published on line.

Seacork Hull is produced without solvants. This improves the air quality inside the cabin and fulfils all current norms for volatile organic compounds.

UPKEEP

SPRAYING

You have to apply at least two or three coats of Seacork Hull to obtain a good result and ensure an effective break in the thermal bridge.

Find all product in the online shop.

DISTRIBUTOR

WHAT OUR CUSTOMERS SAY

The use of cork on boats has a long history and sprayed cork is the latest chapter. Its main

purpose is to prevent condensation inside the hull.

A secondary benefit is the dampening of noise from the water, the wind or an engine.

Seacork Hull was used on the Ecotroll voyage

from Lyons, in France, to Greenland and back in March 2010.

AND MORE

Seacork can implement all kinds of novel ideas with cork sheets and spray. Your own

imagination is the only limiting factor.